Showing all 17 results

-

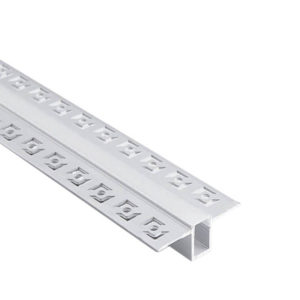

19mm LED Flex U channel aluminum profile with with Transparent or Milky Cover Plastic Connector Clips

$2.10 -

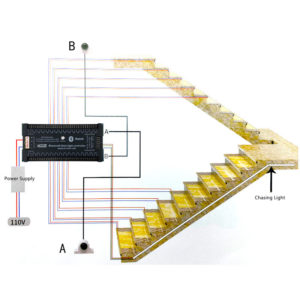

Automatic Bluetooth Stair LED Light Controller Human Body Sensor Smart Stair Light Controller

$55.00 -

Bedroom Bedside Lamp Nordic Minimalist Copper Acrylic Wall Light with Clock Wall Lamps

$16.80 -

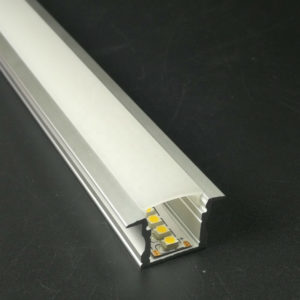

Customized Built in Aluminum LED Cabinet Light Embeded Linear Light Recessed Installation Corridor Lamp

$4.60 -

Embedded Mounted LED Linear Light Bedroom Kitchen Living Room Wall LED Aluminum Profile Channel

$5.50 -

Full Color LED Pixel Point Source Light Outdoor Pixel Strings with Aluminum Profile

$7.20 -

Full Colors RGB Staircase Lighting Wall Automatic Stair Lighting Control Project Installation Smart Sensor LED Stairway

$260.00 -

Hand Scan Sensor Night Light LED Cabinet Lamp 3 Colors Adjustable Under Cabinet Lighting

$2.60 -

Intelligent LED Motion Sensor LED Sensor Stair Strips Light Human Body Induction Motion Sensor Smart Stair Lights

$185.00 -

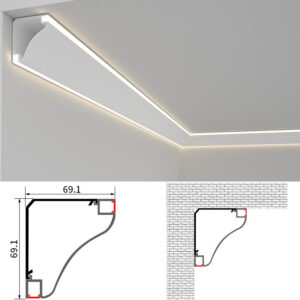

LED Aluminum Profile Linear Light For Gypsum Ceiling Suspended Backlight Linear LED Wall Washer

$9.80 -

Luminous LED Lights for Gypsum Ceiling Free Soft Channel Corner Line Lamp

$9.80 -

Outdoor Aluminum LED Point Light Source Bridge Signboard Lighting Warm White LED Outline lamp

$7.20 -

Permanent RGBW LED Point Light Source Black Aluminum Channel LED Pixel UCS2904 LED Bulbs

-

Removable LED Recessed Stealth Cabinet Wardrobe Closet Light LED Kitchen Bookcase Counter Lamp

-

U Aluminium LED Strip Recessed LED Channel Lighting U Shape Profile LED Lighting Housing

$1.40 -

Wholesale Aluminum Profile for Stair Mounted LED Stair Profile Light For Theater Cinema Stair Step Nosing Light

$5.20 -

Wholesale Wall Lamps Led Linear Light Luminous Lighting Modern Interior decorative Nordic wall lamp

$10.80

LED Aluminum Profiles

It is an innovational LED light environmentally-friendly energy saving bright and it is economical but looks luxurious.

widely used to replace traditional flood light fluorescent lamp in supermarket mall warehouse office school.

Using aluminium profile (extrusion) for mounting LED strip is now the preferred option, particularly for interior use. It can be aesthetically pleasing, as well as providing mechanical support, protection and heat dissipation.

Overview of LED Aluminum Profiles

LED profile is a length of extruded aluminium, typically 2m to 3m long, on to which or into which LED tape is installed. Longer profile results in fewer offcuts, but is more difficult and expensive to transport. It must be packed carefully to avoid being bent.

It generally has a polycarbonate cover which can range from water clear to semi opaque.

The cover clips or slides into place after the LED strip has been installed and tested. The cover provides some degree of protection from moisture and dust ingress. Plastic or spring steel mounting clips are often supplied to secure the profile to its mounting surface, or the profile may be siliconed into position.

Shapes and sizes:While there are now literally hundreds of shapes and sizes of LED profile on the market, the vast majority of applications are satisfied by a few only variations.

The configurations can be summarised

Surface mount, where the profile is mounted on to a ceiling or wall of shelf, sitting proud of it’s mounting surface.Likewise, step light profile may form the leading edge of the step tread, shining down on to the step below.

Shelf light may be standard surface profile, or may be formed to slide on to the glass shelf above, shining downwards. Edge lit variants may light the glass shelf from the back edge.

Suspended profile may be round so as to resemble a bare fluorescent tube, low voltage power often being supplied via the suspension wires. Larger rectangular profiles can support multiple strips of LED, increasing the light output considerably.

Some can include a slim driver inside the profile. Being available up to 3m long means more versatility in the lighting and architectural design.

As mentioned above, profile affords mechanical protection, also against dust ingress and likely moisture to some extent. It makes cleaning more simple, being a smooth, shiny surface.

If the profile is deeper, the increased distance between the LED strip and the cover will be a major contributor in reducing the dot effect. As well, using a tape with higher LED packing density also reduces the dot effect. Using tape of 120 LEDs per metre or greater will generally produce acceptable results.

Viewing angle depends on how far down in the profile the LED strip sits, and also on the design of the cover,LED profile is traditionally clear anodised, but some manufacturers are now offering in black or white, paint or anodise or powder coat. Matching end caps are also offered.

It is of course possible to get clear anodised profile powder coated to any colour locally,In line with current architectural whims, profile is now available in smaller section sizes to as to be less obtrusive in some environments.

Some profile is now bendable, in one plane or the other (not both).

A new type of cover appearing on the market appears black when unlit, then appears white diffused when lit.