LEDVV is a supplier of Wholesale LED strips made with high-quality material and an awesome production process.

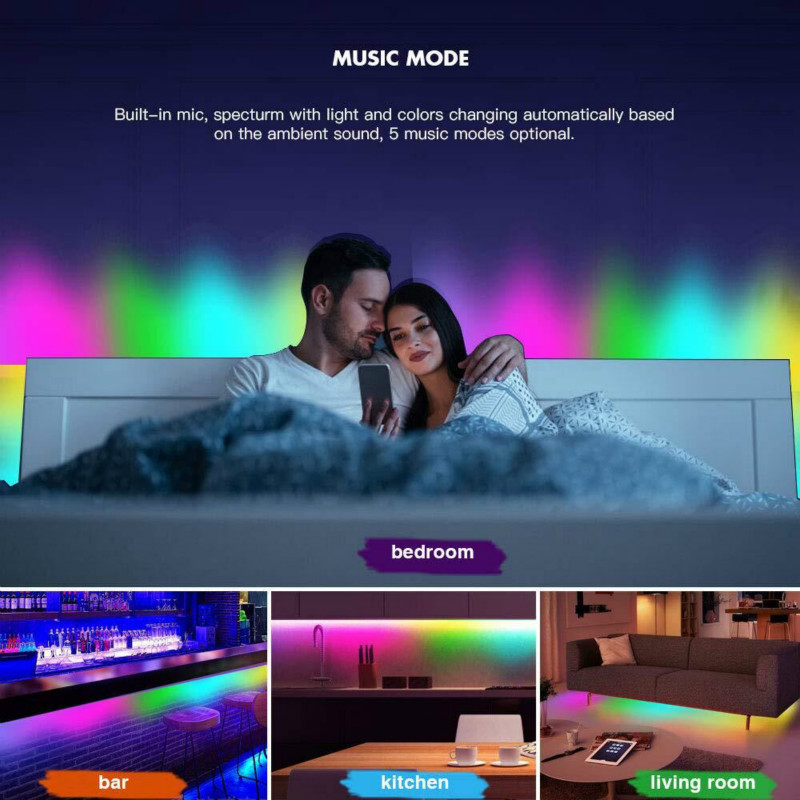

LED strip lights are currently one of the most popular light sources, especially among DIY projects’ enthusiasts, as they are low-profile, easy to set up, energy-efficient and extremely versatile. They’re commonly used for cabinet lighting, for displays or as ambient lighting mixed with other light sources.

Let’s take a look at what exactly they are and how they are produced.

Our production process have been widely application Automated machines,

LED Package Machine, LED Encapsulation Machine, SMD Reflow Owen Machine, SMT Machine, Solder Paste Printer Machine, Extrusion Machine, Aging Test Machine etc.

All these machines ensure us a strong production capacity and perfect quality performance.

What’s more, LEDVV is always on the leading edge of the market, closely focused on market demand, and leading the lighting trends.

Now LEDVV is becoming one of the most powerful and famous OEM/ODM LED product manufacturers in China.

The production process of flexible LED strips(that is FPC strips)as follows:

1. Printing solder paste. After the solder paste is warmed up, stir it, and then put a small amount on the stencil of the printing machine. The amount should be 3/2 of the solder paste when the squeegee advances. *Pay attention to the FPC after a trial printing Whether the solder paste at the LED pad position is full, whether there is less or more tin, and also pay attention to whether there is a short circuit. condition. This check is very critical, and if the check is not strict, it will result in poor quality later on.

2. Patch. Put the printed FPC on the fixture and automatically feed the board to the placement position. The program of the placement machine is pre-programmed. As long as there is no problem with the placement of one board, the production will be stable later. What needs to be noted here is that the polarity of the LED and the resistance value of the chip resistor should not be confused. Another thing to note is that the mounting position should not be shifted.

3. Intermediate inspection links. Need to pay attention to check the polarity of the LED on the LED strip (whether it is reversed), whether the mounting is offset, whether there is a short circuit, whether the resistance value is correct, etc.

4. Reflow soldering. It should be noted here that the reflow temperature must be well controlled. If it is too low, the solder paste will not melt, and cold soldering will occur; if it is too high, FPC will easily foam. Also, the preheating temperature should be appropriate. If the temperature is too low, the flux will not evaporate completely, and there will be residues after reflow, which will affect the appearance; Beads.

5. Finished product inspection. Here you need to check the appearance of the product to see if there are poor soldering, solder balls, short circuits, and so on. Then there is electrical inspection to test whether the electrical performance of the product is intact and whether the parameters

LEDVV keep to Offer High Quality LED Flexible Strip with Competitive Price.

LEDVV guarantees that the LED light Strip from material or production defects with 2-3 years period from the date of purchase. If it is determined defective, we will repair or replace the LED Strip Light. This warranty does not cover appearance damage or damage caused by act, accidents, misuse, abuse, negligence, commercial use or modification of the product or any part thereof. This warranty does not cover damage caused by improper operation or maintenance, connection to an incorrect power supply, or attempts to repair by anyone other than the facility authorized by LEDVV to repair the product.

Repair or replacement under this warranty is the exclusive remedy of the customer. LEDVV shall not be liable for any incidental or consequential damages in violation of any express or implied warranty of the product, and unless prohibited by applicable law, any implied warranty of merchantability or fitness for a particular purpose of the product shall be valid for the duration of this limited warranty.

Only LEDVV may change, amend or modify this limited warranty, and any such change, amendment or modification shall be in writing and issued by LEDVV. For warranty service and shipping information, please send to [email protected].

Finally, the standard warranty period is based on working 12 hours a day. If you need LED Strip lights to support working 24 hours a day, please confirm with us in advance.